Without PCB, none of our devices can work. A PCB is the most important platform to connect various components. Whether you use a phone or computer or a television or a washing machine, take the time to understand the printed circuit card (PCB) which allows it first.

PCB pregregate against Virgin

The prereg and virgin PCB are not the same and they have different uses in the global PCB process. The preprég is nothing more than a layer of insulating material. It is inserted between two hearts or between a nucleus and a copper paper to provide the required insulation. On the other hand, virgin PCBs or naked PCBs can be basic plates in one side with copper on one side or complex multilayer plates with more than 32 conductive layers.

PREREG is the short form of the full word “pre-imperfect”. Essentially, it refers to the fiberglass fabric which has been impregnated with resin which is used in the manufacture of combustion boards. The different types of prereg are fr4 prereg, high tg pregg, ptfe composites, prereg polyamide and not woven aramid pregreg.

Virgins PCB cards form the platform on which all circuit components such as processors, capacitors, switches and chips are assembled. Copper interconnections in layers provide the conduction routes between the different components. This allows effective transmission of power and signals online with the expected circuit functions.

Virgins PCBs offer significant advantages compared to assembly circuits on Perf boards or the use of band cards for prototyping. Their advantages make virgin PCBs integrated into modern electronic design and production. Since printed circuits can be manufactured according to various circuit requirements, they offer extensive flexibility.

PCB Core vs prereg

If the PCB nuclei contain aluminum foil and a copper pre -imprecision, why use pre -only? When designing a board stack at a desired thickness, the pre -impregnated provides additional thickness without adding unnecessary electric layers that would become additions to material and treatment costs.

Simple face PCB VS PCB double-sided VS Multi-Face PCB

A PCB only one side is made from a rigid laminate composed of epoxy woven glass material dressed in copper on one side of the variable thickness. A double -sided board is made in the same way but with copper on two sides. A multilayer board is made with one or more interior nuclei and a copper sheet at the top and bottom. The nuclei can have a thickness between 0.038 ”to 0.005” and the number of nuclei used will depend on the design of the card.

Below, the video shows a PCB only one side with glass epoxy on one side and a layer of copper on the other hand. On a lateral look, the glass epoxy looks like a ceramic tile on the side of a transverse section.

The video below shows a double-sided PCB with a layer of copper on both sides.

Virgin PCB forms

While virgin PCBs are generally presented in rectangular form, circular or triangular or personalized forms are not rare using. Circular virgins are the most common PCBs of rectangular PCBs.

VS Glass Epoxy Mask to weld

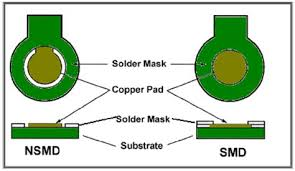

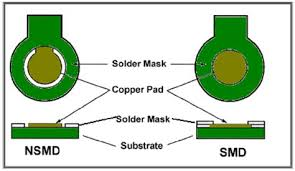

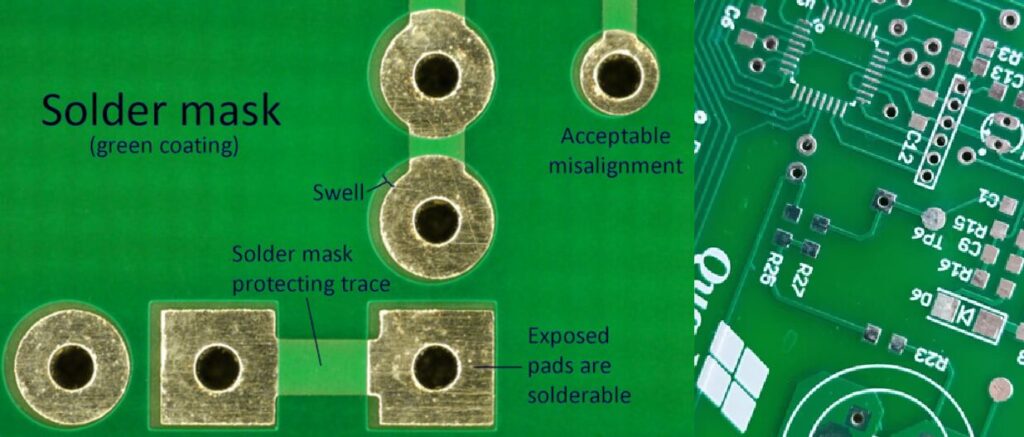

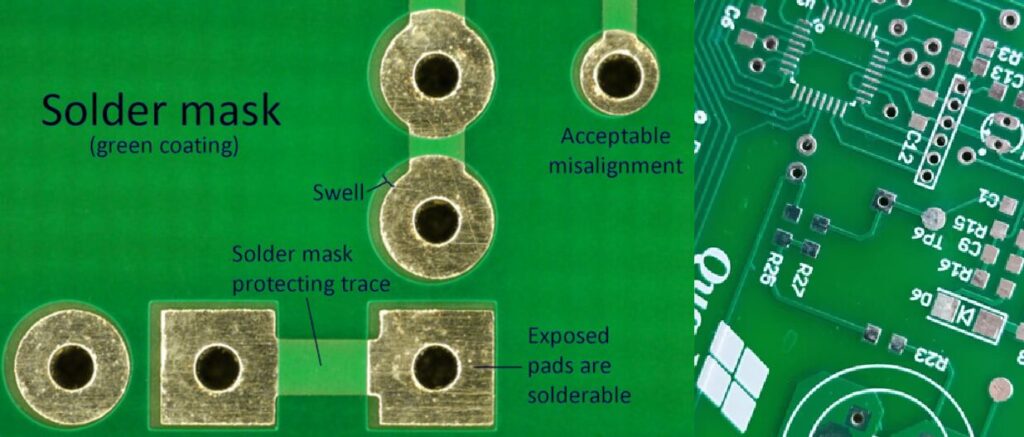

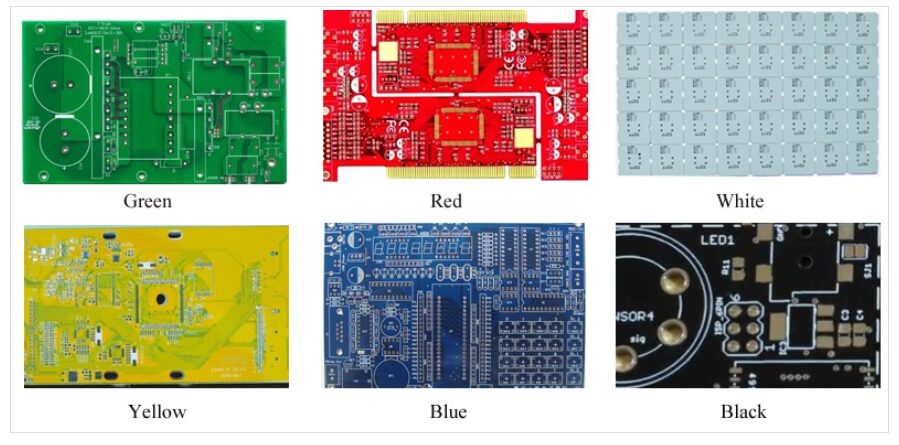

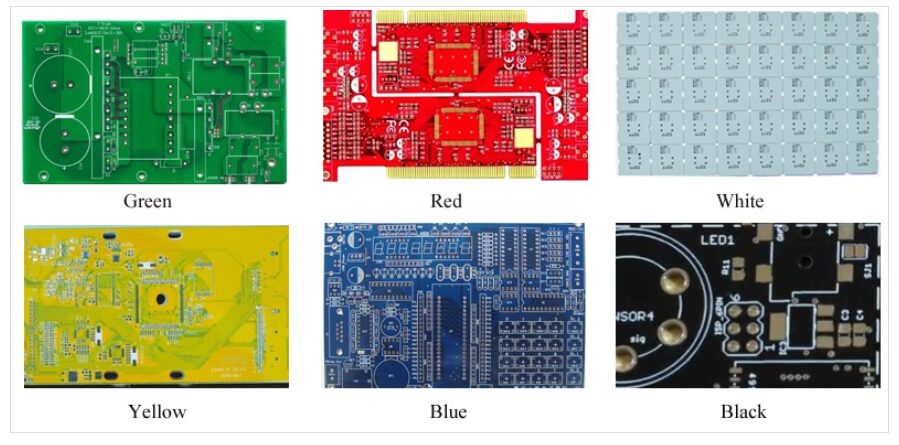

Epoxy glass forms the PCB nucleus substrate. In the PCB nucleus and the welding mask, epoxy is used, however, the welding mask is a protective coating (generally green color although not necessary) of the polymer applied to copper (something like powder coating) to prevent oxidation and prevent short circuits (bridge welding between closely spaced platform).

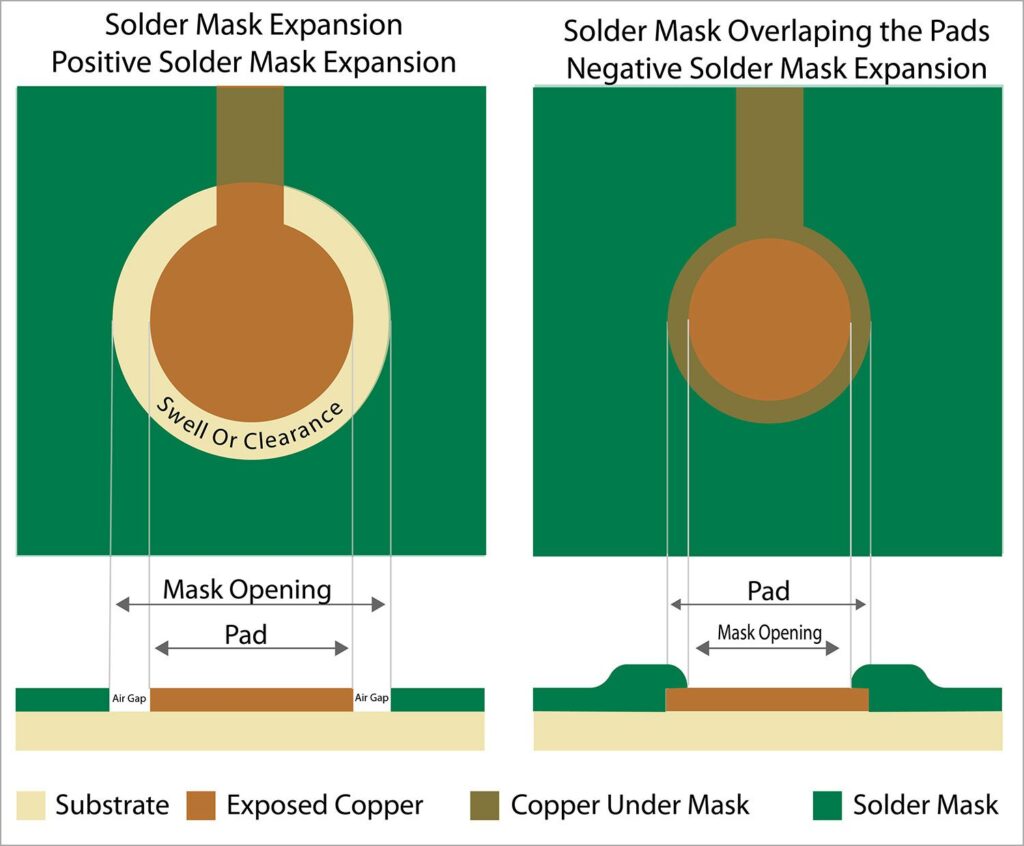

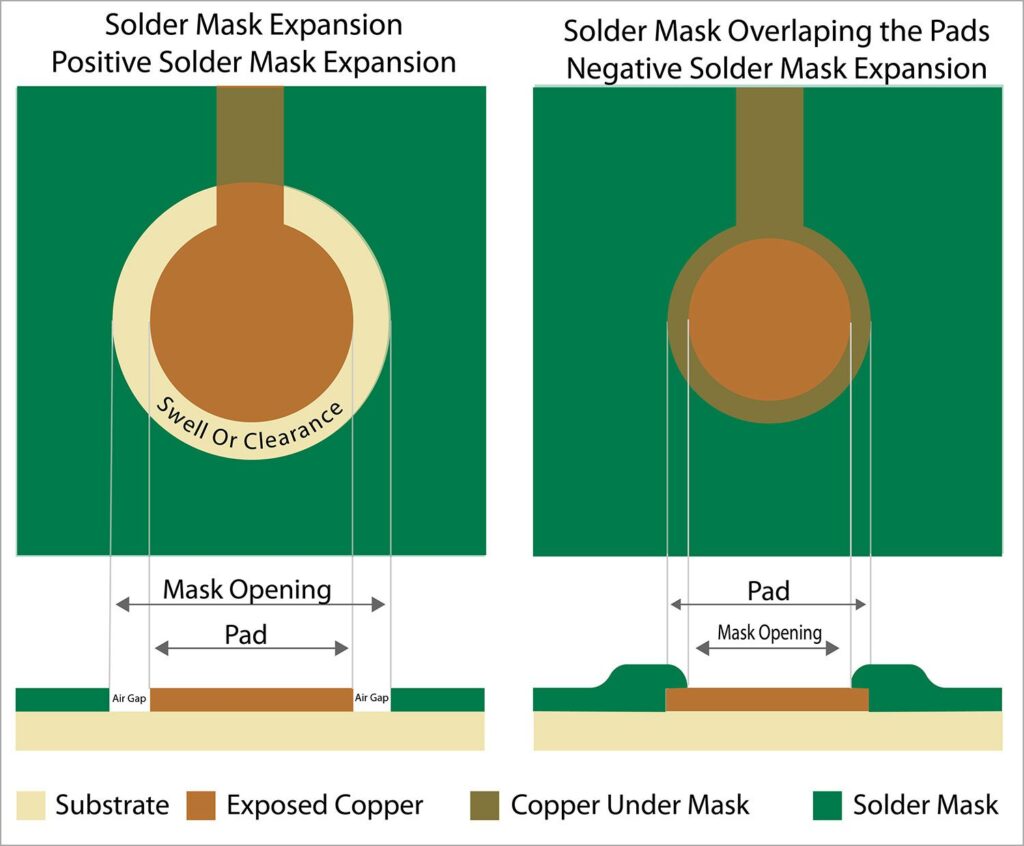

A positive value means that the welding mask will cover a larger area than copper and a negative value means that the welding mask will be smaller than copper.

There are different types of welding masks as shown below.

Inside the PCB

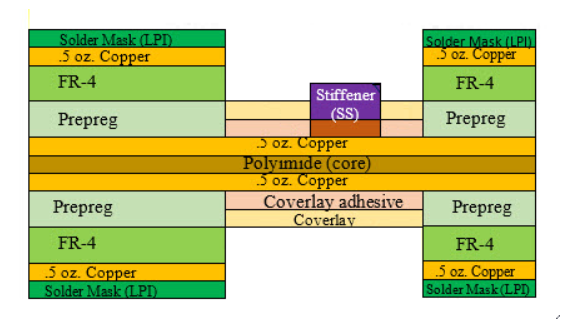

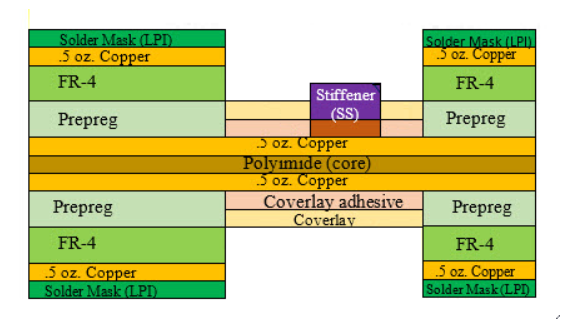

Summarizing all of the above, the transverse section of the interior of a PCB looks like the above.

I hope it's useful, thank you.

You may like to read: Is quantum computer science a threat to encryption?,, Arduino vs raspberry pi vs jetson vs microbit& The clock cycle of a processor